- HOME >

- Experiences >

- Field Experiences >

- Japan >

- Process Safety Study

Process Safety Study

- Client:

- Japanese engineering company

- Country:

- Japan

- Year:

- 2014-2015

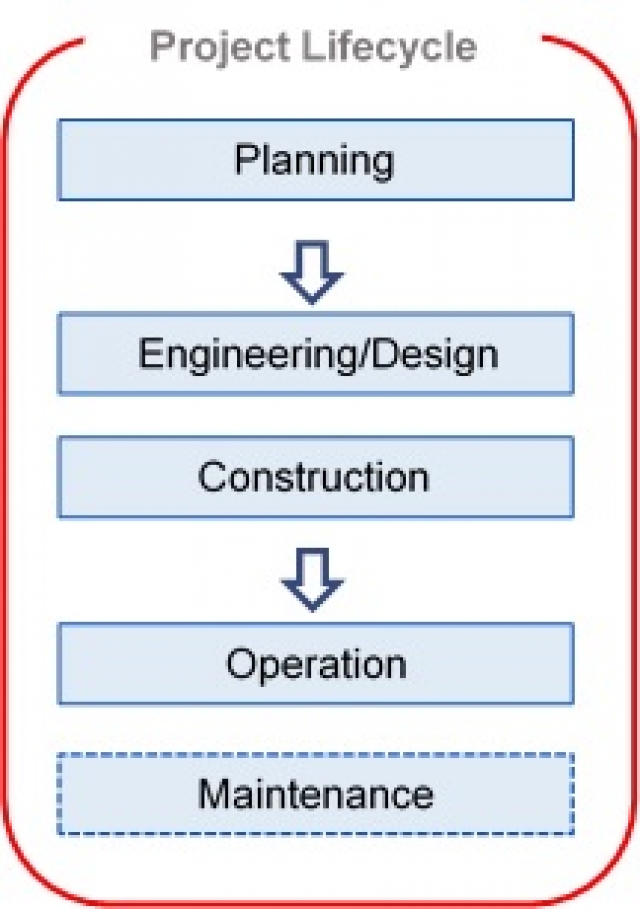

We, JOE, since established, have been seeking assets/operations integrity associated with adequate safety and environmental protection required for stable operation in various consulting and engineering services on planning, design, operation and maintenance of oil and gas facilities in Japan and many oil producing countries.

On the other hand, the E&P sector in the world has been making efforts continuously for more than two decades to discuss advanced methods and management system for “Process Safety” aiming to ensure safety of production facility and operations which is one of the largest objectives in the sector.

According to such trend of the sector in the world, a concept of “Process Safety” as an activity of HSE (health, safety and environment) management has been also considered to introduce to oil and gas industry in Japan as well, and then, the first full-scale of process safety studies on an expansion project of the natural gas production plant was implemented in Japan.

JOE conducted dedicatedly the studies under a prime plant contractor and the outcomes of the studies have been reflected properly to detailed design of the facility and plans for procurement of equipment, construction and commissioning in EPC phase as well as operation and maintenance of the plant after completion of the project.

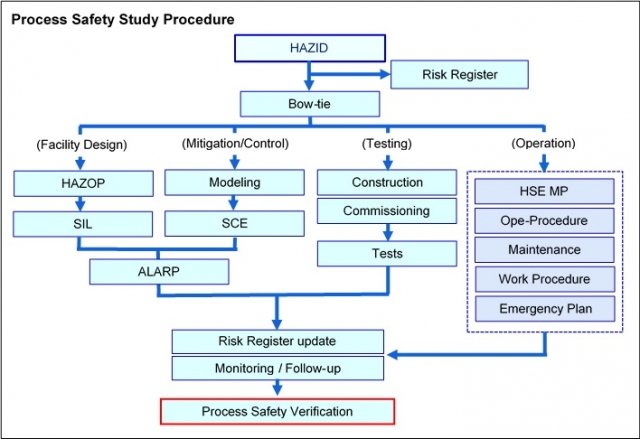

The process safety studies and services conducted for the project include;

1. Identification and assessment of risks on potential gas/ oil release, spill, fire, explosion, etc.

- Hazard Identification Study (HAZID)

2. Study on measures for avoidance/ prevention and mitigation of the risks

- Definition of Safety Critical Elements (SCE)

- Hazardous Operability (HAZOP) Study

- Safety Integrity Level (SIL) Analysis

- Consequence Analysis (Fire/ explosion modeling)

- Bow-tie Analysis

- As-Low-As Reasonably Practicable (ALARP) Study

3. Risk register and follow-up (EPC and commissioning phases)

4. Preparation of “Safety Case”

The above process safety campaign was the first experience for the E&P sector in Japan.

This project was a case of which applied our long-standing engineering and consulting service experiences in oil producing countries as the Middle East and others to domestic oil and gas production facilities.

Regions

Copyright© Japan Oil Engineering Company Ltd. (JOE), All Rights Reserved