- HOME >

- Experiences >

- Field Experiences >

- Japan >

- Plant Design Training

Plant Design Training

- Client:

- Japan Petroleum Exploration Co., Ltd.

- Country:

- Japan

- Year:

- From 2008

PLANT DESIGN TRAINING consists of lectures and exercises about the basics of oil and gas processing facilities and practices of developing a process simulation model of Client’s site and solving any operational problems. The main target of this service is the Client’s site operators working for about 10 years and process related engineers working for 2 to 5 years.

The participants in this training program can acquire and improve their plant design engineering skills in oil and gas processing facilities completely by themselves. In fact, this service has been incorporated in the client’s educational program which shows that the engineering services JOE provided has been highly evaluated and regarded by them.

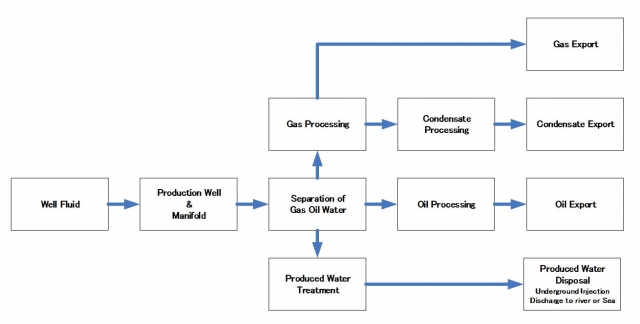

The process basic theoretical lectures are conducted covering all the basic theory, a design, simulation, as well as real operation. Starting with oil and gas production and processing facilities overview, the lectures about hydrocarbon properties, equation of state, and separation facilities are conducted to understand which kinds of properties are used as a basis for designing each processing facility, and exercises about separators sizing, design of oil processing facilities and water processing facilities are also conducted with their tips. Subsequently, lectures and exercises about gas processing facilities which are acid gas treating system, dehydration system, transporting facilities of fluids including pumps, compressors and pipelines are conducted.

JOE provides the training course for the beginners to develop a simulation model by themselves, but in the simulation model developing practice course, the participants were encouraged to develop a simulation model incorporating any oil and gas processing facilities, which was already learned in the process basics theory course.

Regions

Copyright© Japan Oil Engineering Company Ltd. (JOE), All Rights Reserved